PRESSURE to reduce CO2 emissions in cars has led to the development of a “stop-start” system, which automatically switches off a car’s engine when it comes to a standstill in traffic jams or at traffic lights, and restarts it as soon as the driver presses the clutch pedal or releases the brake.

A number of new cars on South Africa’s roads boast this new system – but they are dependent on advanced lead-acid batteries, which are currently only produced overseas and imported by the automotive manufacturers.

Replacing these batteries is expensive and there is pressure for local manufacturers to use locally-manufactured components – two good reasons why the production of these batteries is one of the many energy storage projects on the go at Nelson Mandela Metropolitan University’s newly-launched battery testing laboratory.

The facility is the second independent battery testing laboratory of its kind in the country, the other being the South African Bureau of Standards (SABS).

In addition to the conventional testing of commercial lead acid batteries, which ensures that the battery in your new car, or a replacement battery, complies with the minimum requirements of specified performance, NMMU’s laboratory will also be pioneering national research into new battery technology that will include the testing of lithium-ion batteries for electric vehicles.

“We are the first laboratory in South Africa that will be equipped to do lithium-ion battery testing,” said NMMU battery electro-chemistry expert Prof Ernst Ferg.

“Lithium-ion battery compliance testing is not a simple thing. Due to the nature of the battery and the chemicals involved in its manufacturing, a testing facility must meet stringent safety requirements.

“When the performance of these batteries is tested under extreme conditions of say temperature, or when damaged or punctured during a simulated accident, every precaution needs to be taken to ensure that the resulting fires can be safely extinguished.”

Also in the pipeline at the lab is battery testing and research for the renewable energy field. This includes off-the-grid energy storage, and stand-alone traffic lights, street lights and electric vehicle charging stations.

The laboratory, which opened in May this year, is linked to the university’s Uyilo e-mobility programme (sparked via the government’s Technology Innovation Agency [TIA] initiative), which focuses on national electric vehicle research and development, and is run by NMMU’s engineering technology institute eNtsa.

“When the government gave NMMU the go-ahead to establish the Uyilo e-mobility programme, it was decided in that exercise to include the battery testing laboratory, as batteries are a key component of electric vehicles,” said Ferg, who has 15 years of battery research behind him at the university.

The lab has been set up to conduct standard and specialised simulated battery testing, according to various international battery manufacturers’ and users’ criteria, in collaboration with the local automotive industry. The lab is also conducting research and development with the local battery-manufacturing industry.

“With the ever-increasing competitiveness of the automotive industry, the demand for component suppliers to comply with stringent specifications is increasing. In addition, imported components for the local industry are increasing. To be able to compete, local manufacturers need to provide new battery types that adhere to a range of international testing standards in the shortest possible time, and yet be able to make these batteries cost-effective within their manufacturing environment.”

The lab’s testing equipment includes a 16-channel 100A 18V tester and a high rate 2000A discharge tester with four temperature-controlled water baths and a freezer unit to allow for variable temperature testing. It also has a battery vibrational tester that can evaluate a battery’s performance under a simulated vibrational frequency typically experienced in a driven car.

By early next year, several more testing units will have been installed to allow for higher voltage testing and bi-directional testing.

The research side of the facility, which is located in the university’ chemistry department, has additional battery testing equipment, along with analytical equipment used to study the materials used in the building of batteries.

The lab has a number of collaborative research projects with the international Advanced Lead Acid Battery Consortium (ALABC), whose members include battery manufacturers worldwide. “They are funding research projects that look at new materials, chemistries and applications of the lead acid battery that can make it more efficient to survive the demands of today’s automotive industry and competition with other energy storage systems.”Ferg said there were currently very few pure electric vehicles on the roads in South Africa, with most local automotive manufacturers focusing on producing hybrids that include an efficient fuel engine with an electric battery.

“The lab will be looking at the international testing requirements for batteries in such applications and will eventually be able to work with batteries that are used in stop-start, mild-hybrid, plug-in hybrid and full electric vehicles.

Under the Uyilo programme, a number of pure electric vehicles are being evaluated. These include the Nissan Leaf and the Joule, South African Optimal Energy’s prototype vehicle. The charging infrastructure and energy usage of these vehicles, which make use of large lithium-ion batteries, are being studied by the team.

Also being evaluated are electric game-viewing and rough terrain vehicles (RTVs), which are being used by a local game reserve in their anti-rhino poaching initiatives. “We will look at the performance of the batteries in these in-use vehicles and their use of off-grid charging stations.” - By Nicky Willemse

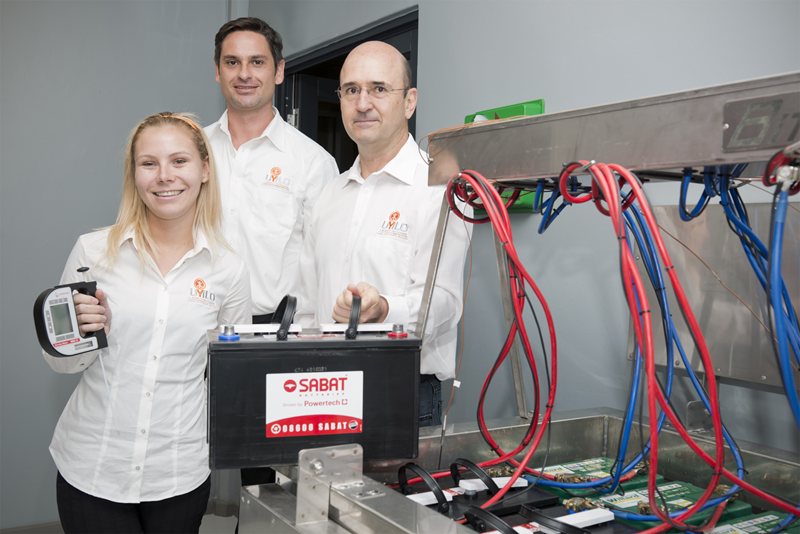

Joining the uYilo battery research leader Prof Ernst Ferg (right) are student Natasha Erasmus and Dr Nico Rust.